Leverage advanced algorithms to analyse data on inventory, shipping, and other factors to

identify areas of inefficiency and suggest ways to improve efficiency. This can include

everything from reorganising the warehouse layout to implementing new processes and

technologies. By streamlining operations, the Warehouse Optimizer can help companies reduce

costs, improve productivity, and increase overall performance.

Problem Statement

Client has over 80 big inventory warehouses (bigger than 5000 sq. m) to store pharmaceutical

products.

Most of the warehouses have manual picking done by operators.

Pickers spend large time on the warehouse floor travelling between different bin locations.

In some automated warehouses, the time taken by final packing team is higher due to line

items coming in different totes.

Key Requirements

Optimize the picking layout to reduce time spent by pickers in the warehouse

Solution Advantages

The solution runs offline without any internet service

On-cloud deployment in client’s VPC.

Solution integrates with client’s SAP system to modify the bin allocation in WMS.

The solution predicts the amount of time required for pickers to pick items for efficient

planning.

On-premise deployment in client’s infrastructure

Fully customizable bank statement formats and analysis output

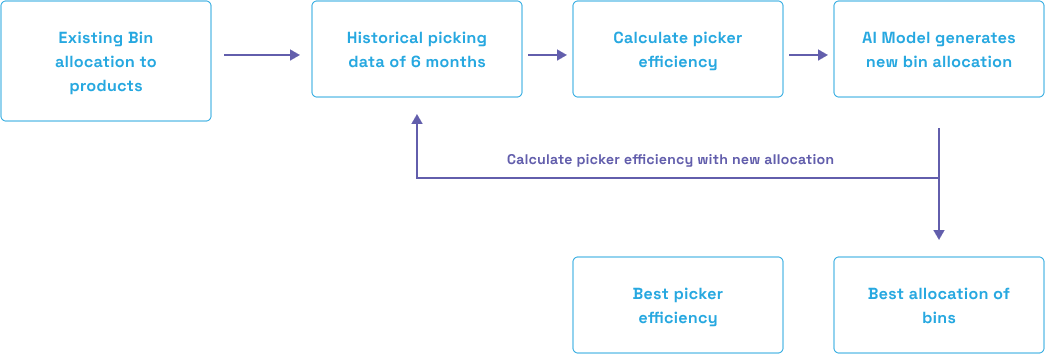

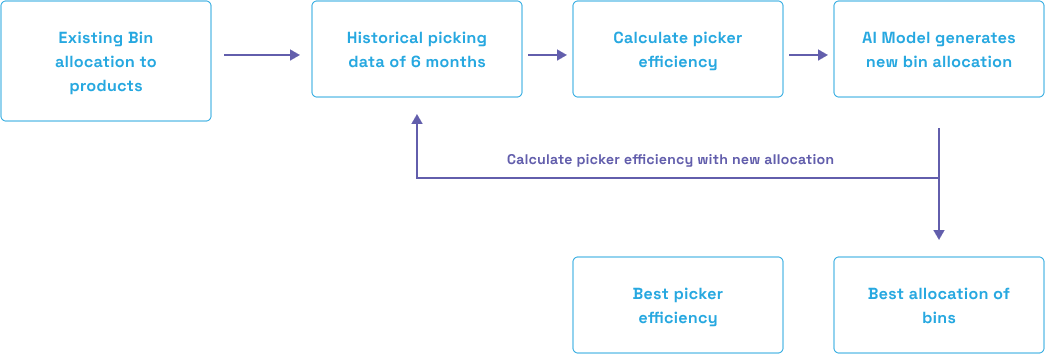

High Level Architecture

Output Accuracy

1.5 hours on average

Time spent after AI

recommendation picking top 20 products

2 hours on average

Time spent before AI

recommendation picking top 20 products

Client Engagement

Data For Training:

Historical data for training – 6 months

No of warehouses – 2 (1 automated and 1 non-automated)

Testing By Client For Goal Achievement:

1 month testing in actual warehouse Efficiency Result = 25% improvement in picker efficiency

Deployment:

Azure, Databricks

Benefit Achieved:

Better planning for workforce in the warehouse

Improved efficiency of pickers

Usage since:

Jun 2022